Patent us20070087878

Table of Contents

Table of Contents

If you’re interested in learning how to draw a sprocket, then you’re in the right place! Sprockets are an essential component in various mechanical and industrial applications, and knowing how to draw them can be a valuable skill. But where do you start? How do you draw them accurately? Don’t worry; we’ve got you covered!

The pain points of how to draw sprocket

Have you ever attempted to draw a sprocket but ended up with an uneven or lopsided shape? You’re not alone. Drawing a sprocket from scratch can be challenging, even for experienced draftsmen. Additionally, there are different types of sprockets, each requiring a unique drawing approach. Getting the measurements wrong can result in a faulty component or machinery.

Answering the target of how to draw sprocket

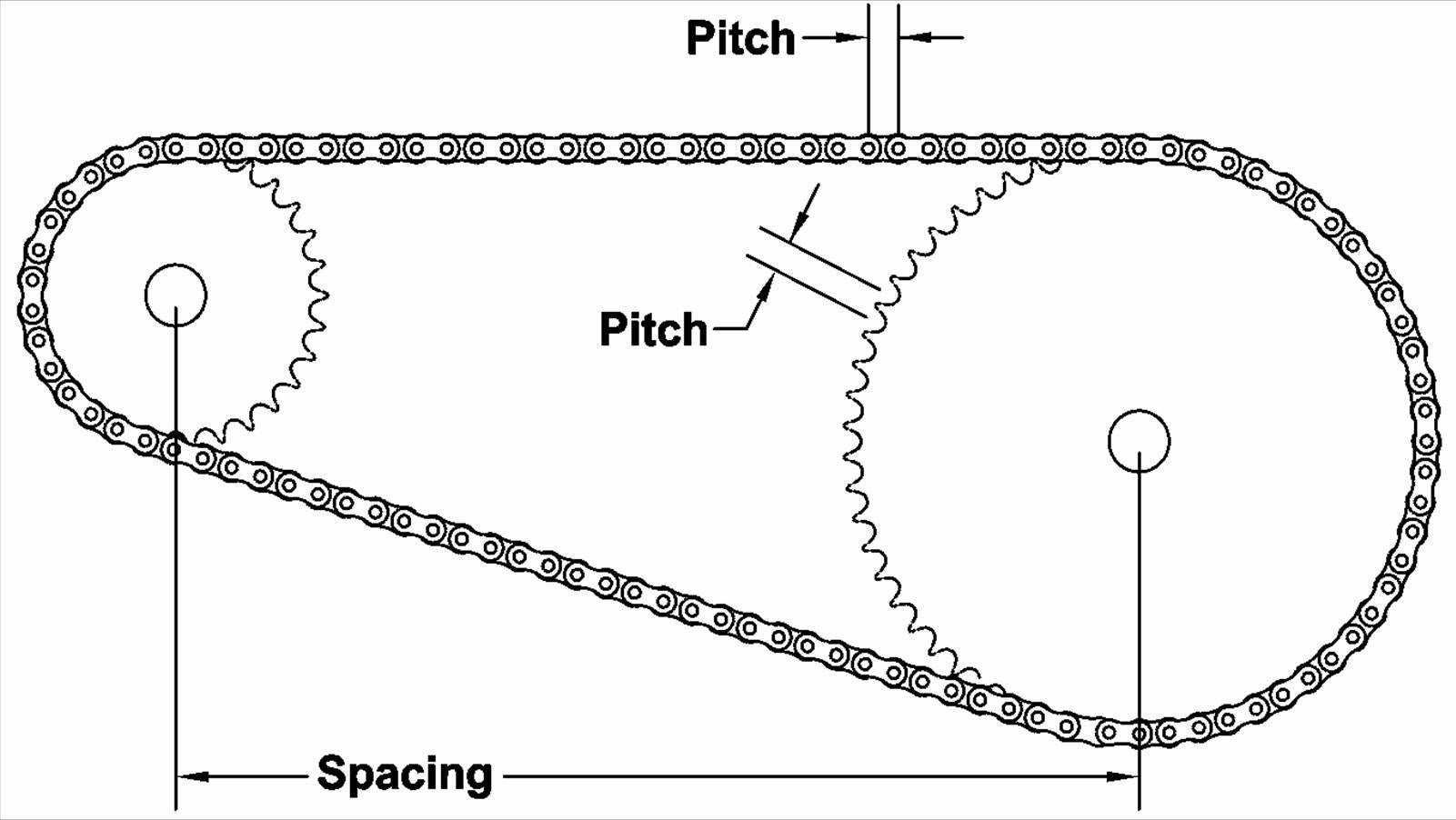

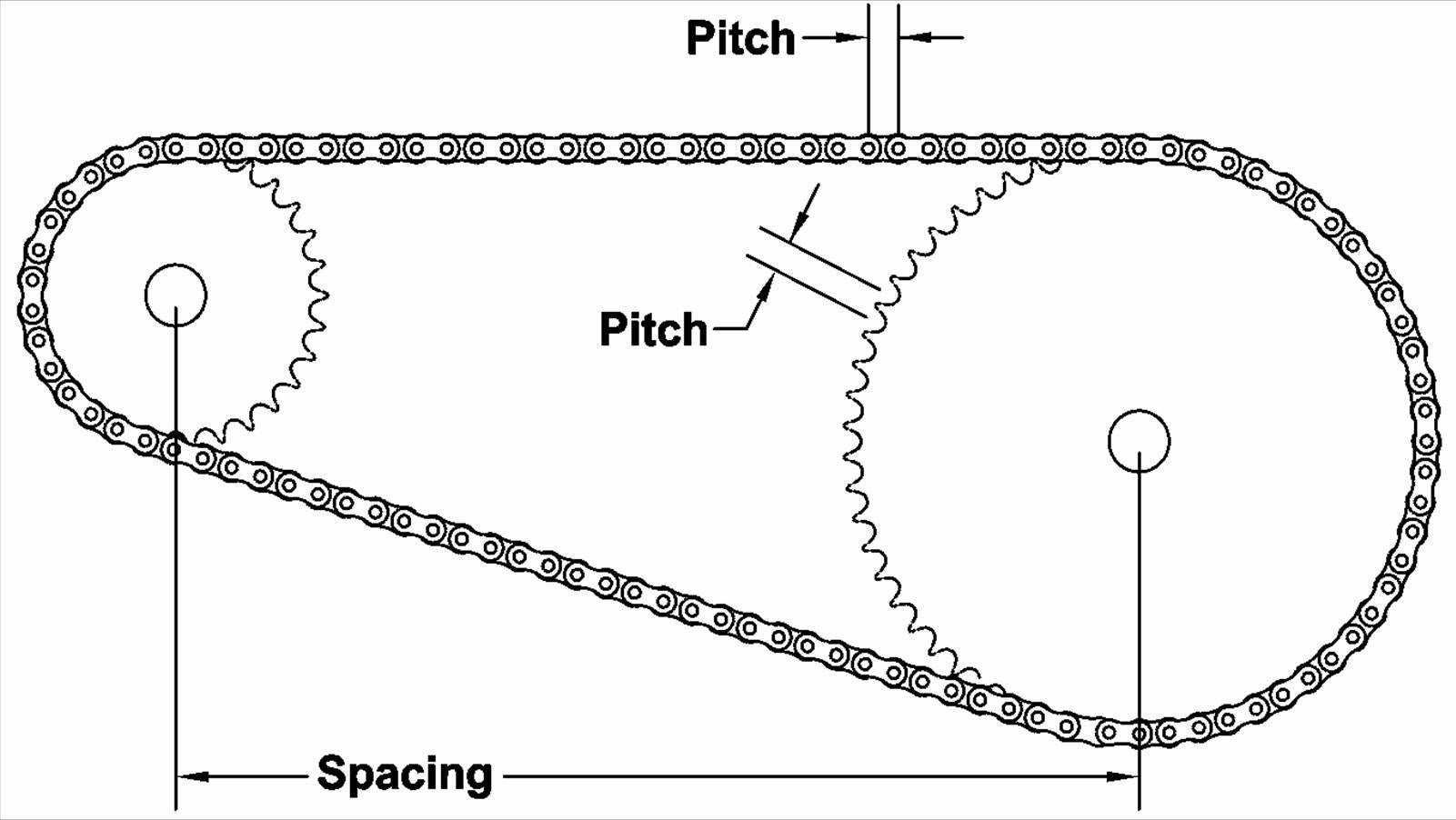

Before diving into the specific steps, it’s vital to understand the basics of a sprocket’s anatomy. A sprocket is a wheel-like component with cogs or teeth that mesh with a chain or belt, allowing rotational motion. To draw a sprocket accurately, you’ll need to understand the number of teeth, pitch diameter, and tooth profile. Once you have a grasp of the basics, you can proceed with the steps to draw your sprocket correctly.

Summary of the article’s main points

In summary, drawing a sprocket may seem complicated, but it’s doable, even for beginners. Understanding the sprocket’s anatomy, including the number of teeth, pitch diameter, and tooth profile, is crucial. Follow the specific steps explained below to ensure that you draw your sprocket accurately.

How to draw sprocket: step-by-step guide

Before proceeding, ensure that you have your drawing tools, including a compass, ruler, protractor, and a pencil. Here are the steps to follow:

Step 1: Determine the pitch diameter and the number of teeth

Sketch a circle and determine the pitch diameter by dividing the circumference of the circle, which is equal to the product of pi and the diameter, by pi. The result is the pitch diameter. Divide the pitch diameter by the roller chain’s pitch value to determine the number of teeth on the sprocket.

Step 2: Draw a base circle and add the teeth

Draw a new circle with the pitch diameter as the radius to create your base circle. Divide the base circle into the respective number of teeth and draw each tooth at an angle. If the sprocket has an even number of teeth, draw the tooth’s tip at the midpoint between two adjacent teeth. If it’s an odd number of teeth, draw the tooth’s tip opposite the midpoint of the tooth space.

Step 3: Draw the crankshaft hole

Draw the crankshaft hole at the center of the base circle. The hole’s diameter must match the crankshaft diameter and be perpendicular to the sprocket’s tooth line.

Additional tips for drawing sprockets

Now that you know the basic steps of drawing a sprocket, you may encounter some challenges along the way. Here are some additional tips to help you:

Tip 1: Use software applications

If you’re not confident in your drawing skills, use software applications like SolidWorks, AutoCAD, or Inventor to create your sprocket designs accurately.

Tip 2: Practice regularly

Like any other skill, practice makes perfect. The more you practice, the better you become, and the more accurate your sprocket designs will be.

Question and Answer Section about how to draw sprocket

Here are some common questions and answers related to drawing sprockets:

Q1: Can I use an existing sprocket to draw mine?

A: Yes, you can use an existing sprocket to determine the pitch diameter and the number of teeth. However, ensure that you’re not copying the shape precisely, as each manufacturer may have unique designs.

Q2: What’s the importance of the tooth profile?

A: The tooth profile determines the engagement of the sprocket and chain, affecting the torque transmission.

Q3: Can I draw a sprocket without a center hole?

A: Yes, you can draw a sprocket without a center hole if it’s unnecessary for your application. However, ensure that the design’s permissible tolerance limits are met to avoid dysfunctionality.

Q4: Why is the pitch diameter vital?

A: The pitch diameter determines the sprocket’s size, affecting its ability to interact with the chain or belt and transmit motion accurately.

Conclusion of how to draw sprocket

Drawing a sprocket may seem complicated, but with the right tools and understanding of the basics, it’s doable. Remember to determine the pitch diameter, number of teeth, tooth profile, and the crankshaft hole. You can also use software applications or practice regularly to improve your skills. Lastly, ensure that you’re not copying existing designs for precise measurements or tolerances.

Gallery

Patent US20070087878 - Standard Sprocket For Chain - Google Patentsuche

Photo Credit by: bing.com / sprocket patentsuche

How To Draw A Sprocket Gear : 5 Steps - Instructables

Photo Credit by: bing.com / sprocket engrenage pignon kettenrad zahnrad mehrere kettenräder getriebe instructables gewusst kraftübertragung dyi gegenüber manchmal vorteile practice

Draw Sprocket | Gear | Circle

Photo Credit by: bing.com / sprocket

How To Draw A Sprocket In Solid Edge

Photo Credit by: bing.com /

Patent EP0886085B1 - Sprocket Wheel With Improved Tooth Profile For Greater Silentness - Google

Photo Credit by: bing.com / sprocket tooth profile patents drawing wheel